Tungsten Alloy Applications as per ASTM B777-15

(Also known as Mallory 1000®, Densalloy®, Fansteel 77® and Densimet®)

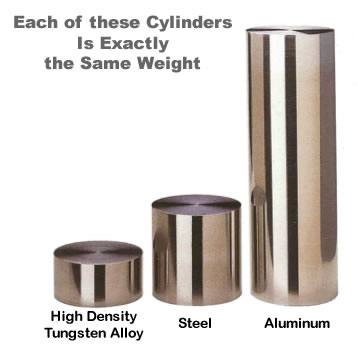

Tungsten has become an essential material in a wide range of applications spanning numerous industries. Tungesten Alloys provide a design solution for many applications requiring concentrated weight in a limited space. These alloys also provide radiation shielding due to their density which is 1.5 as times effective as lead.

Tungsten Alloy Shielding Applications

Generally speaking, the absorption rate of X-rays and gamma radiation is directly proportional to the density of the shielding material. Since Tungsten Alloys are denser than lead, these alloys can be up to one and a half times more effective than lead, and provide extremely efficient protection from radiation sources, especially in applications where space is limited.

|

|

|

Tungsten Alloy Counterweight, Balancing, and Vibration Dampening Applications

Due to their high density (approximately 50% denser than lead), Tungsten Alloys have found wide application in fixed and rotary wing aircraft, gyroscopic and commercial balancing applications. The ability to fit a denser material into a smaller volume of space is essential to these applications. In addition, Tungsten Alloys have properties similar to mild steel and are machinable. These alloys can be plated and painted to user’s specifications. Where lead will creep at ambient temperature, Tungsten does not exhibit this characteristic.

|

|

In fixed wing aircraft, Tungsten Alloys are utliized in the control surface areas, ailerons and flaps, empennage areas for vertical and horizontal stabilizers as counterbalances. For helicopters, weights are incorporated in the forward and rear rotor blades for static and dynamic balancing as well as for vibration reduction.

For commercial applications, Tungsten Alloys are used as counterweights in high performance engines, weights in golf heads to increase the “sweet spot” and professional darts.

Tungsten Alloy High Temperature Tooling

Tungsten Alloys are employed for aluminum die-casting and extrusion dies where conventional tooling equipment lacks the wear resistance and the toughness required at elevated temperatures.